Which Grease Trap?

Grease trap, greasetrap, grease separator, fat trap are all interchangeable names used for a "container" that is connected to your wastewater outlet, predominantly from the wash up and preparation sinks in your commercial kitchen.

This container can be made of a number of different materials including mild steel, and high density polyethelyne (HDPE) or similar. Where space permits an outside underground grease trap with a large capacity (300 litres plus) maybe the preferred solution.

These traps can be either internal or external to your premises both above and below ground level.

How Do I Choose A Grease Trap or Grease Management System?

If your grease trap is situated outside of your building or kitchen space, when it's time to service and remove the accumulated waste, this can be carried out without interruption to your normal business activities avoiding odour pollution, which can be disruptive and offensive to both customers and staff.

All grease traps require periodic servicing, and waste removal, to ensure they continue to perform and protect your drainage from blockages, foul odour and potential pest infestation.

Grease trap waste is regarded as a controlled waste by the environment agency and you have a duty of care to provide documentation to confirm a registered waste carrier has managed the removal of waste accordingly.

Underground Grease Traps

You should consider:

- Available space and access for maintenance, service and periodic waste removal

- Ground works costs and feasibility

- Drainage levels and isolation of any foul waste from entering the trap from any other drainage source

- Professional cleaning and servicing is required to remove and dispose of the waste

- Volume of meals prepared, kitchen best practice and type of premises are variables which will determine an optimum grease trap sizing along with the other points above

Benefits:

- An underground grease trap is outside and will not interupt your kitchen service or present an odour issue when being serviced

- Generally larger than equivalent in building / in-kitchen grease traps and therefore requiring servicing less frequently

- No daily or weekly cleaning or maintenance required by kitchen staff saving time and money

- No risk of cross contamination and health, hygiene and safety benefits for staff or customers

No space for an outside underground grease trap

There are a number "point of source" in-kitchen grease traps and Grease Removal Units (GRU), which are generally installed close to the pot wash and spray off sink. In many cases the pot wash and spray off sinks are in the same area or close to the food preparation and cooking areas.

Often there is limited space in the kitchen and smaller units are therefore the only option available.

In-Kitchen Grease Trap

You should consider:

- Available space and access for maintenance, service and periodic waste removal

- Initial cost of the grease trap with ongoing costs

- Ongoing costs including electricity, daily / weekly staff maintenance time, ongoing service and waste removal, professional servicing, maintenance and spare parts

- Professional cleaning and servicing is required to remove and dispose of the waste

- Volume of meals prepared, kitchen best practice and type of premises are variables, which will determine an optimum grease trap sizing along with the other points above

- Health, hygiene and safety practice

Benefits:

- Waste is trapped and managed at source

- Efficient method of grease management where space is limited

- No need for disruptive ground work or construction

- A range of products available at affordable cost

* G-Bag Grease Trap System is a cost effective, in-kitchen grease trap that has gained popularity and awards for it's innovative design and function.

The waste is trapped and sealed in the G-Bag, which means there is no need for daily kitchen staff cleaning or maintenance.

The health, hygiene and safety benefits are obvious alongside odour control and reduction when its time to change the G-Bag.

What is a GRU - Grease Removal Unit

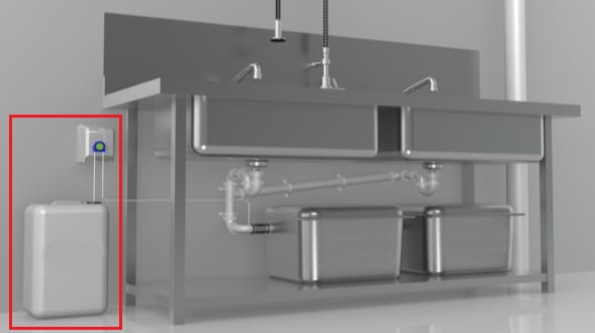

Grease removal units or systems are electrical and mechanical units plumbed to the pot wash and spray of sinks in a similar way to passive grease trap.

Instead of trapping the waste they unit seperates the fats, oils and grease from the wastewater and removes it to a collection contianer attached to the machine. The units noramally contain or are sold with a food solid filter basket or pre-filter system.

You should consider:

- Available space as GRU's normally require more available space, electricial supply, additional plumbing

- Initial cost of GRU prices range from £1800 with an average cost £3,000 plus installation

- GRU's require daily staff cleaning and maintenance

- Ongoing costs including electricity, daily / weekly staff maintenance time, professional servicing, maintenance and spare parts

- Volume of meals prepared, kitchen best practice and type of premises are vairables, which will determine an optimum grease trap sizing along with the other points above

- Health, hygiene and safety practice - cross contamination risks

Benefits:

- Waste is trapped and managed at source

- Collected waste fats, oil and grease can provide a small revenue

- Effective grease management

Grease Drain Dosing Protection

Where there is no space in your kitchen or outside your building, a stand alone Grease Drain Dosing system will provide you with protection from the build up of fats, oil and grease in your drainage system.